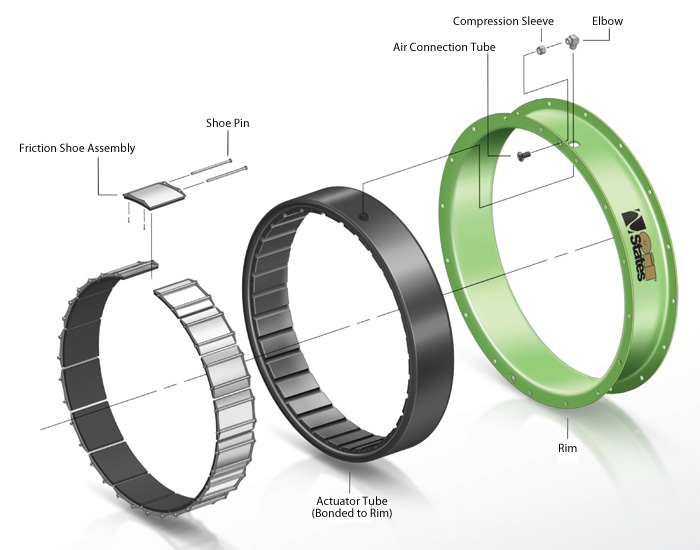

CB SERIES CLUTCH AND BRAKE

Reliability, low inertia and simplicity of design make this an excellent choice for high-speed, cyclical clutch operations and low-to-medium torque systems. Its integral rim/tube construction provides a highly adaptable solution, and the tube design compensates for imperfect alignment in the driving system while delivering a smooth transfer of power.

I'd like to request a quote.

FEATURES AND BENEFITS

| Size | CB SINGLE FLANGE TORQUE LB-IN |

CB DUAL FLANGE TORQUE LB-IN |

CB DUAL CLUTCH TORQUE LB-IN |

|---|---|---|---|

| 4CB200 | 1,000 | - | - |

| 6CB200 | 2,040 | - | - |

| 8CB250 | 4,290 | - | - |

| 10CB300 | 8,150 | - | - |

| 14CB400 | 19,700 | 19,700 | 39,400 |

| 16CB500 | - | 35,200 | 70,400 |

| 18CB500 | - | 44,000 | 88,000 |

| 20CB500 | - | 53,600 | 107,200 |

| 22CB500 | - | 62,300 | 124,600 |

| 24CB500 | - | 75,000 | 150,000 |

| 26CB525 | - | 92,400 | 184,800 |

| 28CB525 | - | 106,000 | 212,000 |

| 30CB525 | - | 121,000 | 242,000 |

| 32CB525 | - | 137,000 | 274,000 |

| 36CB525 | - | 172,000 | 334,000 |

| 40CB525 | - | 211,000 | 422,000 |

| 42CB525 | - | 260,000 | 520,000 |