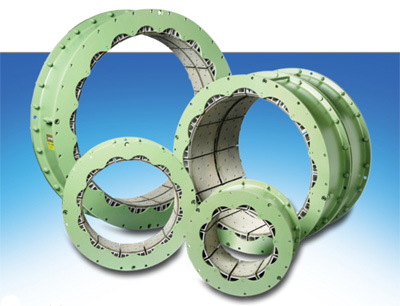

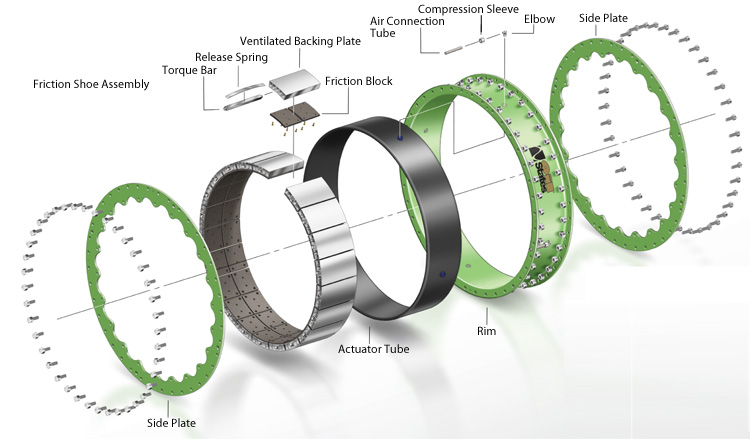

VC SERIES CLUTCHES AND BRAKES

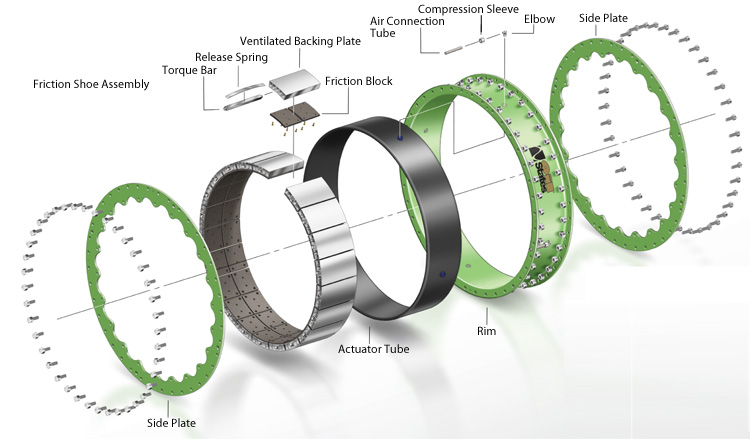

Ideal for severe high torque applications, the VC brake serves as a durable, high thermal capacity drum clutch

or brake. The unique design of the ventilated friction shoe assembly allows for a high volume of air flow across the entire

shoe length, enhancing heat dissipation, preserving the elastomeric actuator tube and extending overall clutch life. Virtually all

components used in the VC design are replaceable.

I'd like to

request a quote.

FEATURES AND BENEFITS

| Size |

VC SINGLE NARROW

TORQUE LB-IN |

VC DUAL NARROW

TORQUE LB-IN |

| 11.5VC500 |

27,000 |

54,000 |

| 14VC500 |

39,200 |

78,400 |

| 16VC600 |

65,000 |

130,000 |

| 20VC600 |

93,000 |

186,000 |

| 24VC650 |

135,000 |

270,000 |

| 28VC650 |

182,000 |

364,000 |

| 33VC650 |

255,000 |

510,000 |

| 37VC650 |

320,000 |

640,000 |

| 42VC650 |

380,000 |

760,000 |

| Size |

VC SINGLE WIDE

TORQUE LB-IN |

VC DUAL WIDE

TORQUE LB-IN |

| 14VC1000 |

85,000 |

170,000 |

| 16VC1000 |

114,000 |

228,000 |

| 20VC1000 |

161,000 |

322,000 |

| 24VC1000 |

219,000 |

438,000 |

| 28VC1000 |

296,000 |

592,000 |

| 32VC1000 |

415,000 |

830,000 |

| 38VC1200 |

680,000 |

1,360,000 |

| 42VC1200 |

819,000 |

1,638,000 |

| 46VC1200 |

950,000 |

1,900,000 |

| 52VC1200 |

1,215,000 |

2,430,000 |

| 51VC1600 |

1,610,000 |

3,220,000 |

| 60VC1600 |

2,183,000 |

4,366,000 |

| 66VC1600 |

2,800,000 |

5,600,000 |

Oil States Clutches

Made in USA

Made in USA

PARTS, ACCESSORIES AND REBUILD KITS

To complement our Elasta-Flex VC clutch and

brake technology, we sell a broad selection of

accessory components as well as rebuild kits

to extend the life of your equipment. We offer

long-wearing drums, hubs, and spiders; rotary

couplings; pneumatic quick release valves and

a variety of hardware components to tailor each

solution to your specific application.

| |

Construction and Friction Shoe

Assembly Options |

| 1 |

Single Mounted, one-piece rim construction and standard

non-asbestos friction material |

M |

Same as "1" with extended side plate and bolting block |

| A |

Single Mounted, one-piece rim construction and high

coefficient friction material - HI-CO |

Q |

Same as "1" with special side plate |

| B |

Dual Mounted, one-piece rim construction and standard

non-asbestos friction material |

R |

Same as "1" with extended side plate |

| C |

Dual Mounted, one-piece rim with HI-CO friction material |

S1 |

Same as "1" with 3/4-16UNF inlets |

| D |

Single Mounted w/ one-piece single-flange rim, standard

non-asbestos friction material |

T |

Same as "1" with split tube |

| E |

Single Mounted, two-piece split rim and standard nonasbestos

friction material |

1A |

Same as "1" with hard steel side plate |

| G |

Dual Mounted, one-piece rim, standard friction material

w/ one side connection |

RS |

Same as "1" with split extended side plate |

| H |

Single Mounted, one-piece single-flange slotted

rim and standard friction material |

Q-1 |

Same as "1" with Ideco extended side plate |

| J |

Same as "1" with solid side plate |

BZ |

Same as "1" with special steel side plate |

| K |

Same as "B" with solid side plate |

W |

Same as "1" with special extended side plate |

| L |

One side plate with flat head screws |

M-1 |

Same as "1" with extended side plate less bolting blocks |

KEVLAR

PROTEC THERMOFIBER 1600 CUSTOM DISC PADS

THERMOFIBER 1600 is a unique material designed for

both wet and dry applications. This material offers

exceptionally low wear rates, high & stable friction coefficient

and smooth running, even at elevated

temperatures. TF1600 polishes mating surfaces,

virtually eliminating wear.

Besides these features, TF 1600 has been designed

with ecology in mind. The material runs cleanly with

LOW BRAKE DUST. The manufacturing process employ

no hazardous contaminating products or by-products

such as copper or lead.

Available in all sizes & forms. Also available in VC/CM

expander clutch tire-tube lining. A powerful nonconductive

insulation effect provides an additional 100F

heat resistance provides extra safety margin.

I'd like to

request a quote.

|

TECHNICAL DATA |

| COLOR |

Green |

| COMPOSITION |

|

| Metallic |

No |

| Aramid |

Yes |

| MAIN FIBER |

Kevlar |

| TYPE OF SERVICE |

Dry-Wet |

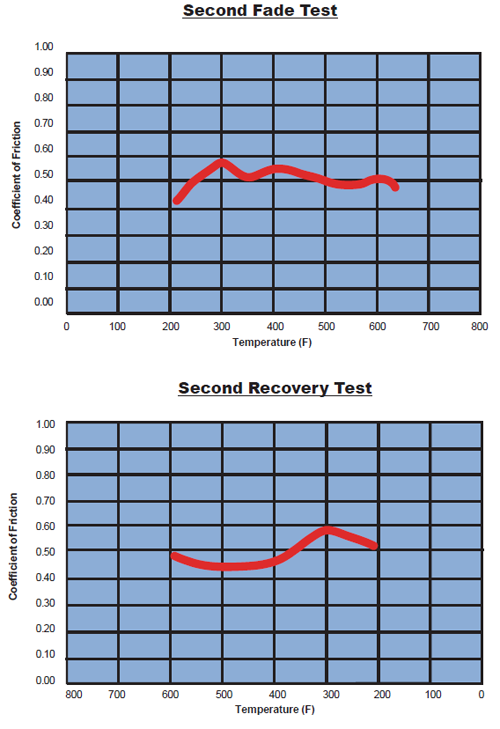

| COEFFICIENT OF FRICTION * |

0.52 Normal |

| |

0.50 Hot |

| WEAR RATE ** |

Excellent |

| SHEAR IMPACT STRENGTH |

High |

| MECHANICAL RESISTANCE |

|

| Burst Strength |

>18,200@ 400 F (200rpms) |

| Tensile Strength |

3,985 psi |

| Compressive Strength |

4,438 psi 10%(UNE-EN ISO 604) |

| Ult Compress Strength |

52,174 psi (UNE-EN ISO 604) |

| HARDNESS |

80 |

| SPECIFIC GRAVITY |

1.0 |

| MAX. DRUM TEMPERATURE *** |

762 F |

| MAX. PRESSURE |

IP424756 |

| AVAILABLE FORMS |

|

| Radius Blocks |

|

| Gear Tooth Facings |

|

| Disc Brake Pads |

|

| Clutch Facings & Buttons |

|

| Flat Sheets |

|

| Special Molded Pieces |

|

|

*According to CHASE Test SAE-J661-A, Note: Tested by Link

Testing Laboratories-Michigan-USA. **Values calculated 400

F (204 C), 150 PSI, 20 ft/sec data point is typical of standard

operating conditions, not the maximum limits of the

compound. Wear rates vary with changes in temperature,

pressure, and speed. Parameters- excellent: 0.006/0.008,

good: 0.009/0.011 moderate; +0.012. ***Feet/Min constant

operation |